Developing beautiful color coatings and compelling visual effects for new vehicles lies at the heart of Axalta’s technology.

Over the lifetime an average vehicle is on the road, repairs are inevitable. Getting the color on the repaired surface to match the existing shade on the remainder of the vehicle can be significantly improved by Axalta products and application technologies that optimize the entire coating refinishing repair process.

Digitizing Color

To reproduce the correct color, Axalta’s advanced digital color tools identify, weigh and mix the precise ingredients required to repaint a car in the body shop. These color tools contribute to sustainability in the repair process by reducing waste, saving time and improving their productivity by allowing them to select the right color formula the first time, mix it accurately and apply it with confidence.

- The new handheld Acquire Quantum EFX spectrophotometer is placed on an undamaged and cleaned area of paint and, by reading that color from different angles, determines the correct formula for the new paint that will be sprayed on the area to be repaired.

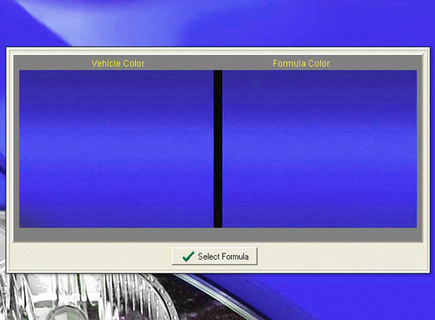

- Axalta’s ColorNet 2.0 Web Formula Retrieval System uses unique vehicle identification numbers (VIN) to retrieve the factory-applied color formula. However, paint can change over time due to exposure to sunlight and the elements. When that happens, the painter then pairs the Quantum EFX with ColorNet’s shading algorithms to refine the formula and find the best color match. Colors can be compared visually on the ColorNet monitor without wasting any paint using the Axalta Color Proofing system to ensure the correct variant is selected and mixed.

- Axalta's digital resources ensure the color formula is correct and, using the XPERT weighing system, all materials needed to produce the desired color are weighed accurately the first time. This minimizes paint waste, saves time and reduces the cost of materials and repair.

Savings from Digital Technology

Source: Autocraft XPERT Analysis

Syrox Coatings Turn Refinish Upside Down

Syrox™ is based on completely new European coating formulations and offers a complete and compact refinish coating system for passenger car repair. It is designed for body shops of all sizes that want an easy to use and economical way to repair and repaint vehicles. Both the chemistry and first-of-its-kind packaging add to the ability of Syrox to contribute to sustainability in the body shop. Axalta’s spectrophotometer technology with its access to more than 70,000 color formulas quickly finds the latest color formulas online. Great first-time color match reduces waste that can result from the need to adjust color by remixing using more paint..

- The water-based composition of the color base coats reduces the environmental footprint from the coating process with a product that has low emissions of volatile organic compounds (VOCs).

- To reduce waste from poor measuring, special dosing lids on squeezable bottles allow accurate pouring, to the drop. Bottles also come in convenient smaller volume sizes and only need a shake before use. A level indicator window on the side of the bottles shows users when the contents are getting low.

- The unique flat-topped bottle cap that covers the dosing lid enables the bottles to stand upside down so that no product is wasted.

Axalta’s spectrophotometer technology with its access to more than 70,000 color formulas quickly finds the latest color formulas online. Great first-time color match reduces waste that can result from the need to adjust color by remixing using more paint.

Sustainable Refinishing with Cromax EZ

Cromax™ EZ is Axalta’s newest premium waterborne base coat color coating system for body shops. Because of their sustainability benefits, waterborne base coats are the preferred product in premium body shops operating in markets where VOC emissions are limited, such as in most of North America, which adheres to so-called National Rule VOC limits (670 grams per liter) and even lower limits (340 grams per liter) in California and Canada.

- To accelerate the color matching process and reduce waste, Cromax EZ has a complete set of chromatically sorted color chips to allow easy, manual selection of the right color for a repair.

- Digital color matching technology is also available using the Acquire™ Quantum EFX spectrophotometer, which uses digital color measurement technology to obtain the precise color formula drawn from Axalta’s digital color library. Refinish technicians can quickly identify and get the correct color the first time, reducing waste that can result from poor matching.