Axalta coatings find many applications that contribute to sustainability goals in the course of new building construction and the restoration of existing structures.

Building Responsibly and Beautifully

Aluminum is a material of choice for building facades and many other architectural and everyday products. Axalta’s Eloxal™ Selection of Alesta® powder coatings combines chemistry and color to provide a beautiful finish that prevents corrosion while reducing environmental impacts. Powder coating technology replaces traditional liquid applications that rely on a chemical process to anodize the metal to protect the surface and requires an additional coating to provide a decorative effect. The Eloxal process provides a highly durable surface that meets leading architectural and industry standards around the world. The protective benefit and colorful finish choices and metallic effects are combined into a single coating process.

- Eloxal coatings eliminate the use of hazardous chemicals (and their waste) required in the traditional anodizing process.

- No volatile organic compounds (VOCs) are emitted during the application of the powder coating on the substrate.

- Eloxal’s super durable rating means that coated materials receive both a beautiful finish and underlying protection against corrosive environmental elements that will last for decades and preserve resources.

Adding Years to Old Structures

Axalta’s water-based Hydropon™ spray-applied field repair coating can transform the appearance of an old roof or siding into looking brand new. The product can extend a structure’s years of service and provide a new color without affecting the environment.

- Waterborne technology significantly reduces emissions compared to solventborne alternatives.

- Air-dry technology means Hydropon can be applied in the field without the need for high temperature curing. This conserves resources by repainting rather than replacing structures and doing so without energy required to cure the coating.

- Durable performance translates into the ability to withstand extended exposure to humidity, temperature extremes, UV and acid rain.

- A smooth finish enables newly coated surfaces to resist mold and mildew, staying clean longer and reducing maintenance costs.

- A combination of cool and high reflectivity pigments reduces energy use by directing heat away from the building, lowering the burden on air conditioning systems.

- Reflective properties and cool pigments also combine to help reduce urban heat island effect and lower ambient outside air temperatures.

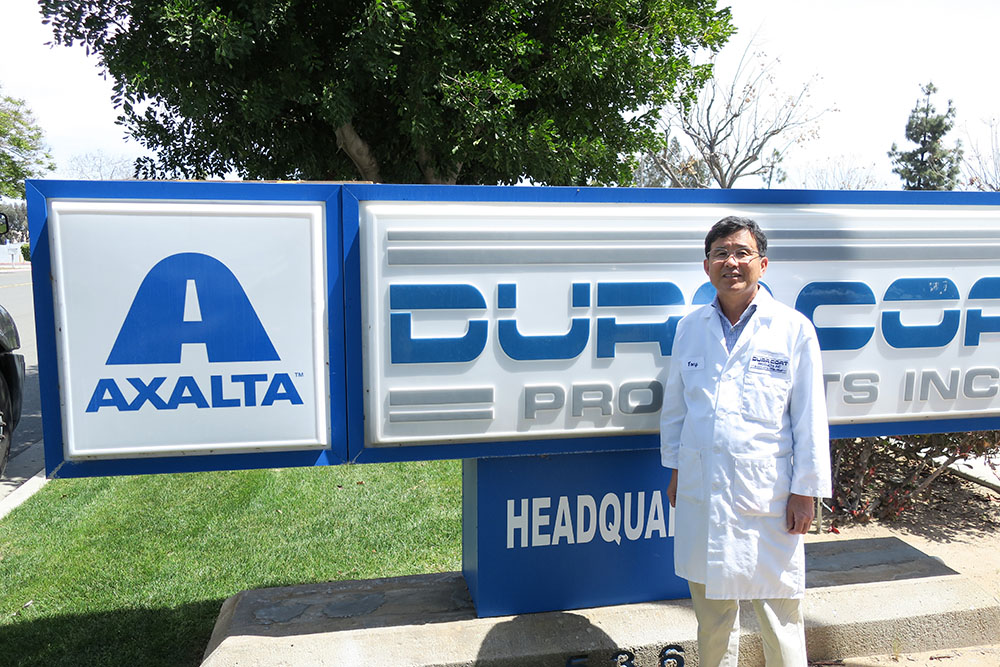

“Our challenge in developing Hydropon was its application and durability in the most severe environments. For example, painted metals in tropical, coastal or highly humid climates, which expose materials to salty sea fog and wind and strong ultraviolet light, are what Hydropon is especially designed for.”Tony Kim, Director, Research and Development, Dura Coat Products, Inc., an Axalta Coating Systems Company

Protecting and Adding Beauty to Aluminum

Durapon™ 70 HS high-solids spray coatings shine in monumental and commercial applications constructed with extruded aluminum such as storefronts, curtain walls, railings and trims.

- High-solids chemistry reduces the ratio of solvent to color pigments, lowering the emissions of VOCs during application.

- Advanced formulation allows for use straight from the container without the need to add solvents before applying.

- Ready-to-use packaging increases productivity by cutting application time and cost.